The economy right now is more than a little unpredictable. Businesses around the world are facing unprecedented events, and many are quickly trying to adapt in response.

Inventory forecasting is one of the strategies some businesses are using to adapt to today’s less-than-stable economy. In this post, we’re going to discuss how forecasting inventory levels in today’s economy can be so essential in helping you stay profitable and keeping cash flow high.

What Is Inventory Forecasting?

Inventory forecasting is the process of looking at your current and past sales records to predict what supply you may need and how long it will take to get in.

Inventory forecasting is useful in any economy. A restaurant may know that they need to order twenty bags of coffee beans every except December, when they only need fifteen bags because people are more prone to ordering seasonal drinks. This prevents over-ordering, and ensures that you’re making strategic decisions about your supply that increases profitability.

While useful in general, inventory forecasting has become increasingly essential in today’s economy. Let’s take a look at why.

It Allows You to Adapt to Shifts in Consumer Behavior

Right now, consumer behavior is shifting quickly. As people are suddenly laid off and are spending more time at home, their buying patterns will naturally change.

Inventory forecasting based not only on past sales but also expected changes in consumer behavior will be particularly useful right now. Grocery stores, for example, are selling out of yeast, poultry, and canned beans like never before.

Look at your current situation, and consider what your audience will want. Think about price points they can afford, and what will be more immediately valuable to them. An auto shop, for example, may see less optional upgrades or enhancements, so reducing orders on supplies for those projects would likely be a good call.

It Helps You Prioritize High-Value Items When Times are Tight

Right now, times are tight. There’s no getting around that. Many businesses are struggling to manage cash flow when they saw their sales reduce almost overnight. While there are relief funds that may be useful for some US businesses, improving cash flow with inventory forecasting can also make an enormous impact.

Careful inventory forecasting can help you assess which items will be most high-value and fast-selling. Look for items that sell the quickest and for the highest profit, or that are expected to be most in demand.

By prioritizing high-value items, you’ll be able to order in the products that will sell fastest and earn you the most revenue, improving your cash flow and keeping you from spending too much capital on unnecessary assets. This will also drive more sales overall in the long run.

You Can Adapt to Slowed-Down Delivery Times from Suppliers

Previously, if you ordered toilet paper from a supplier, you might get it within a week or even a few days. Now, if you need to restock, it may take several weeks to receive that same shipment.

Today’s economy is tough for everyone, and it’s not uncommon for businesses to experience slower-than-normal delivery times from their suppliers and manufacturers. This can be caused by shipping or importing issues, or even having a manufacturing plant shut down entirely due to the virus. This can impact the entire supply chain, and result in much longer wait times before you see the products you’ve ordered.

This recently happened with common medicines, including some antibiotics and ibuprofen, because the areas responsible for manufacturing generic drugs in India restricted their export with little warning.

If you’re using inventory forecasting to watch what you need in advance, this will typically give you enough lead time to check on delivery times and order any supply needed far in advance.

There May Be Less Manual Labor Involved

Cutting costs is a goal many businesses share, but this is especially true during crises.

Accurate inventory forecasting may mean that there’s less manual labor involved from your staff, helping with both of these key concerns. You’re ordering in more of what you need and less of what you don’t, and forecasting allows you to automate the process and predict labor needs more efficiently.

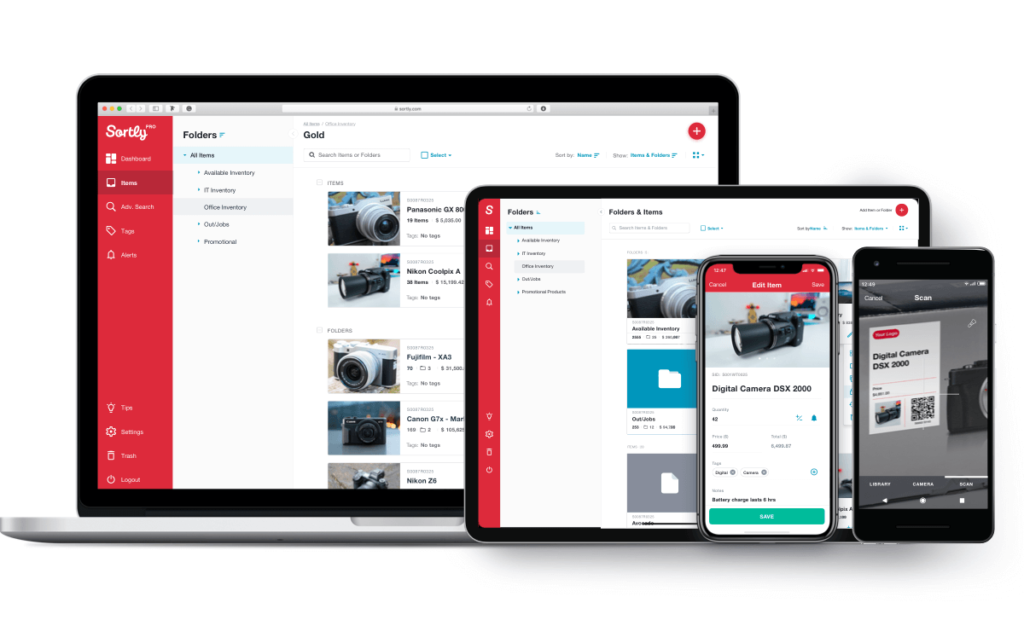

Keep in mind, too, that inventory management tools like Sortly allow you to manage your inventory from anywhere. If you’re looking to temporarily reduce the number of staff members on the floor at any given point, your inventory manager can keep an eye on everything from a remote location– even if they got stuck halfway around the world before shelter-in-place orders were enacted.

Conclusion

Inventory forecasting should be a standard part of inventory management and ordering for your team, but it’s even more crucial now in today’s economy. It will help you stock the right items, prevent you from wasting valuable capital on items that won’t sell, reduce the likelihood of supply delays, increase sales, and cut costs.

Inventory management tools like Sortly can help with inventory forecasting. You can use our alerts features to stay on top of any items that need to be reordered, whether it’s because you’re running low in stock or because they’re close to expiration. You can also review which products are your fastest sellers, and adapt your current ordering limits based on your new forecast.

Interested in using inventory forecasting to help your business thrive? Start your free trial with Sortly today!