No matter your business’s size, understanding inventory turnover is a necessity. In this article, we’ll define inventory turnover, provide expert tips on how to improve inventory management, and explore how inventory management software can help you calculate and leverage your inventory turnover rate.

Inventory Turnover Definition

Inventory turnover refers to how many times a company has sold and replaced inventory over a specific time period, typically a year. Inventory turnover is important because it reveals whether your business stocks excessive inventory, relative to what your company actually uses or sells. Optimizing your inventory turnover rate and only keeping what you need in stock helps your business stay efficient and profitable.

Inventory turnover ratio is the ratio between sales or usage and current inventory in stock. For example, if you sold 500 units of inventory last year and had 500 units in your warehouse, then your ratio is 1 (1:1).

Other terms for inventory turnover include inventory turns, merchandise turnover, stock turnover, stock turns, and turns.

What does inventory turnover measure and tell me about my business?

Inventory turnover tells you how well inventory is moving through your business. When a business knows how to measure inventory turns properly, it means there is good inventory management, which leads to greater profit over time. After all, you wouldn’t want to keep valuable inventory and supplies in stock if you’re not going to use them to provide goods or services—those funds could be better used elsewhere to build your business.

You can also compare your turn ratio to past averages over the same duration of time to see how sales and inventory turnover are comparing from one period to the next.

Here is what inventory turnover tells you:

- How often you are restocking and moving inventory

- If you are holding too much inventory

- If your inventory is too low

- If you are making correct buying choices based on what you think your vendors, clients, customers, or even patients will need

- If you need better marketing efforts

Knowing how to properly understand and calculate your inventory turnover can lead to promising news for your business. Are you selling inventory quickly or does the majority of your inventory tend to sit in the warehouse? Should you be ordering more inventory to increase sales? Should you try to market your merchandise differently? When you know your inventory turns ratio, it will be easier to confidently answer these questions.

But first, you need to know how to calculate your inventory turnover ratio.

What is the inventory turnover formula?

There are a few steps to calculating your inventory turnover, including first calculating your Average Inventory and Cost of Goods Sold. Keep in mind each time period is different depending on the industry, so periods will range from yearly to quarterly or monthly.

Cost of Goods Sold is also known as Cost of Sales or Cost of Services.

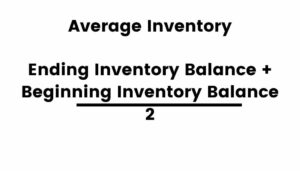

Step 1: Calculate Your Average Inventory (AI)

Your Average Inventory (AI) is a calculation (or a very good estimate) of the value of your company’s inventory over a set period of time. You can obtain this information by looking at your closing inventories and opening inventories.

Your Average Inventory (AI) is calculated by: (Your Ending Inventory Balance + Your Beginning Inventory Balance) / 2

Example: Your ending inventory balance is $150,0000. Your beginning inventory balance is $50,000. Divide that by two and your Average Inventory is $100,000.

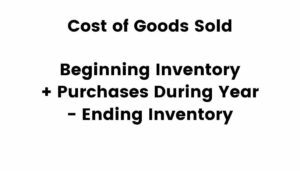

Step 2: Calculate Your Cost of Goods Sold (COGS)

Cost of Goods Sold (COGS) is also known as Cost of Sales or Cost of Services. The Cost of Goods Sold is a calculation for all the costs involved in selling your merchandise. This includes the expenses and costs of goods manufactured and merchandise that was sold.

It is calculated by: Beginning Inventory (costs at the beginning of the year) + Purchases During the Year – Ending Inventory (inventory at the end of the year)

Example: Your beginning inventory was $50,000. Purchases totaled $300,000. Your ending inventory was $150,000. $50,000 + $300,000 – $150,000 gives you a COGS of $200,000.

Other calculations business owners sometimes like to calculate with the COGS number are gross income and net income.

Gross Income is your Gross Revenue – COGS

Net Income is your Revenue – COGS – Expenses

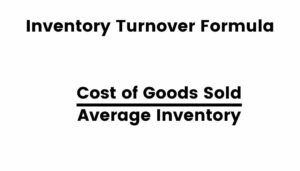

Step 3: Calculate Your Inventory Turnover Ratio

Your inventory turnover ratio is calculated by: Cost of Goods Sold / Average Inventory = Inventory Turnover Ratio

Experience the simplest inventory management software.

Are you ready to transform how your business does inventory?

How to calculate inventory turnover

Here’s an example of how to calculate your own inventory turnover:

Let’s say your Cost of Goods Sold was $200,000. Again, that is the total cost of what was used to produce your sold products (including things like cost of materials, warehousing costs, and direct labor expenses). And then let’s say your Average Inventory was $100,000 (what your products were valued at). $200,000 / $100,000 is 2.

That means over the course of that year, you turned inventory two times.

How should I use inventory turnover statistics?

Your inventory turnover ratio is viewed as being either low or high. The ratio can be interpreted to provide more insight into your business, stock and sales.

High inventory turnover means:

- Product is being sold or used very quickly

- Less “cash” is being held up in inventory

- Generally, industries that have a high inventory turnover are going to have merchandise that frequently expires, like chemicals or medical supplies

- You have balanced supply and demand

But you still want to be careful that your inventory isn’t too high. Higher inventory turnover could suggest that your business is buying and holding onto more stock than it truly needs. This, too, is problematic for a variety of reasons.

When your inventory turnover is too high:

- Overstocked items might expire or fall out of warranty before they can be used or sold

- Capital used to buy deadstock could be better used otherwise, such as hiring new team members

- You may be overstocking, which can be a symptom of an inefficient inventory strategy that saps time and money

On the other hand, low inventory turnover means:

- Inventory is not moving quickly

- You overestimated the demand for your product

- Your business is losing money due to inventory having to be held in a storage facility

- Products might have to be discounted or tossed, which again results in lower sales and profit

- You’ve purchased large amounts of product due to the holiday season and potentially large sales

For example, let’s say your business stocks inventory for landscaping purposes. Your inventory turnover ratio was a 2, which would be considered very low, since you only had two turns over the course of a year. You could interpret that to mean a few different things, such as you have low demand for some of your landscaping assets (like sprinkler pipes) and should stock your inventory with items in higher demand (like mulch). It also means you are limiting profits by allowing supplies to sit on the shelf for so long.

By reviewing your inventory turns, you can get insight on which products you should purchase and stock more of and which products you should stop purchasing.

Of course, your business could be different. As an interior designer, for example, you might see an item at an antique show and buy it on the spot, knowing very well it could be years until you start the project it’s perfect for.

What is a good inventory turnover?

What makes an inventory turnover rate “good” really depends on your industry, as different industries will have different sale seasons and different inventory turnovers. That being said, it is generally considered to be a good ratio if it is between 4 and 6. This number typically indicates that your inventory management is strong, your inventory has a shorter shelf-life and the items you stock are moving frequently and consistently.

To give you an example, if your auto parts business had an inventory turnover ratio of 4, that would mean you turned over your inventory four times in one year. And turning over inventory four times usually means your supply and demand is in balance, giving you a strong turnover ratio.

What is deadstock?

Deadstock, also known as Obsolete Inventory, is merchandise that was never sold. It’s usually the result of too much product being ordered, as demand did not meet expectations. Deadstock limits your potential sales returns because you have spent money on your merchandise and that merchandise was not sold. This is a direct loss for your business.

Deadstock is almost always the case of poor inventory management.

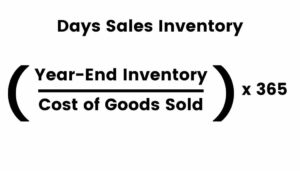

What is Days Sales Inventory (DSI)?

Days Sales Inventory (DSI) gives you the average number of days inventory was held. The keyword with DSI is average.

You can calculate this by: (Year-end Inventory / Cost of Goods Sold) x 365

For example, if your year-end inventory was $150,000 and your Cost of Goods Sold is $200,000, your DSI would be 273.75. That means your inventory will turn every 273.75 days, indicating profits are tied up for almost a year. That’s not ideal for gross sales and profits… but, of course, your business could be different.

How inventory software can improve your inventory turnover

The best solution for monitoring inventory is inventory management software. Sortly makes it easy to track your inventory turnover on an ongoing basis because it centralizes your inventory data in one easy-to-use platform. You can get up-to-date inventory counts and values for every item you track—so you can more easily identify what items are moving too quickly or not quickly enough for optimal turnover. This helps you reduce your deadstock and improve your inventory turnover. You can also ensure the accuracy of your turnover rate because with Sortly, your whole team will be tracking inventory in real time as inventory is consumed or moved, thanks to our easy-to-use mobile app.

Optimizing inventory turnover is just one small piece of how Sortly can benefit your business. Sortly lets you organize, track, and manage inventory—from any device, in any location. Our easy-to-use mobile app lets you and your team update inventory on the job, scan barcodes from your smartphone, set low stock alerts to remind you to re-order, and more. That means you can work more efficiently, plan for jobs better, and serve your customers to their highest satisfaction.

If your business would benefit from improved inventory management, try Sortly free for 14 days.